影响塑胶模具钢使用寿命的因素有哪些?塑料模具钢是模具钢的三大类之一,塑胶模具钢具有较高的热强性和热疲劳性,是比较传统的典型钢种,比较适合加工材料。塑胶模具钢在投入使用的周期,影响塑胶模具钢的使用寿命因素有哪些呢?下面七和模具小编告诉大家。

What are the factors affecting the service life of plastic mold steel? Plastic die steel is one of the three categories of die steel. Plastic die steel has high thermal strength and thermal fatigue. It is a traditional typical steel and is more suitable for processing materials. What are the factors affecting the service life of plastic mold steel during the service cycle of plastic mold steel? The following seven and mold Xiaobian tell you.

塑胶模具钢材性能质量

Performance and quality of plastic mould steel

钢材质量的决定性因素,选择合适的模具钢材是重中之重。比如注塑材料不同,相应的模具钢料也不会相同,如对高抛光的要求、耐腐蚀的要求等等;塑料模具钢一般P20模具钢的寿命在30万左右,可以根据情况选择。这是决定塑胶模具寿命的重中之重。

Steel quality is the decisive factor, and the selection of appropriate die steel is the top priority. For example, if the injection molding materials are different, the corresponding mold steel materials will not be the same, such as the requirements for high polishing, corrosion resistance and so on; Plastic die steel generally has a service life of about 300000 P20 die steel, which can be selected according to the situation. This is the top priority to determine the service life of plastic molds.

塑胶模具钢材表面处理

Plastic mould steel surface treatment

塑胶模具钢材的表面处理也是非常重要,氮化能够增强钢材的表面硬度,有用延长模具寿命;电镀能对模具钢材进行有用改性,对一些需要高亮度的和耐腐蚀的塑件可以利用电镀来增强和改进钢材的性能。

The surface treatment of plastic mold steel is also very important. Nitriding can enhance the surface hardness of steel and prolong the service life of mold; Electroplating can effectively modify die steel. For some plastic parts that need high brightness and corrosion resistance, electroplating can be used to enhance and improve the performance of steel.

成熟的模具结构不但考虑到产品材料属性、收缩率、成型温度、弹性拉伸变形系数等,而且还要考虑到冷却水路、开合模的速度等。合理的模具结构能有用延长模具寿命和保证模具的顺利生产。提率,降低成本。

The mature die structure not only takes into account the product material properties, shrinkage, forming temperature, elastic tensile deformation coefficient, but also takes into account the cooling water path, mold opening and closing speed, etc. Reasonable die structure can effectively prolong the die life and ensure the smooth production of the die. Improve efficiency and reduce costs.

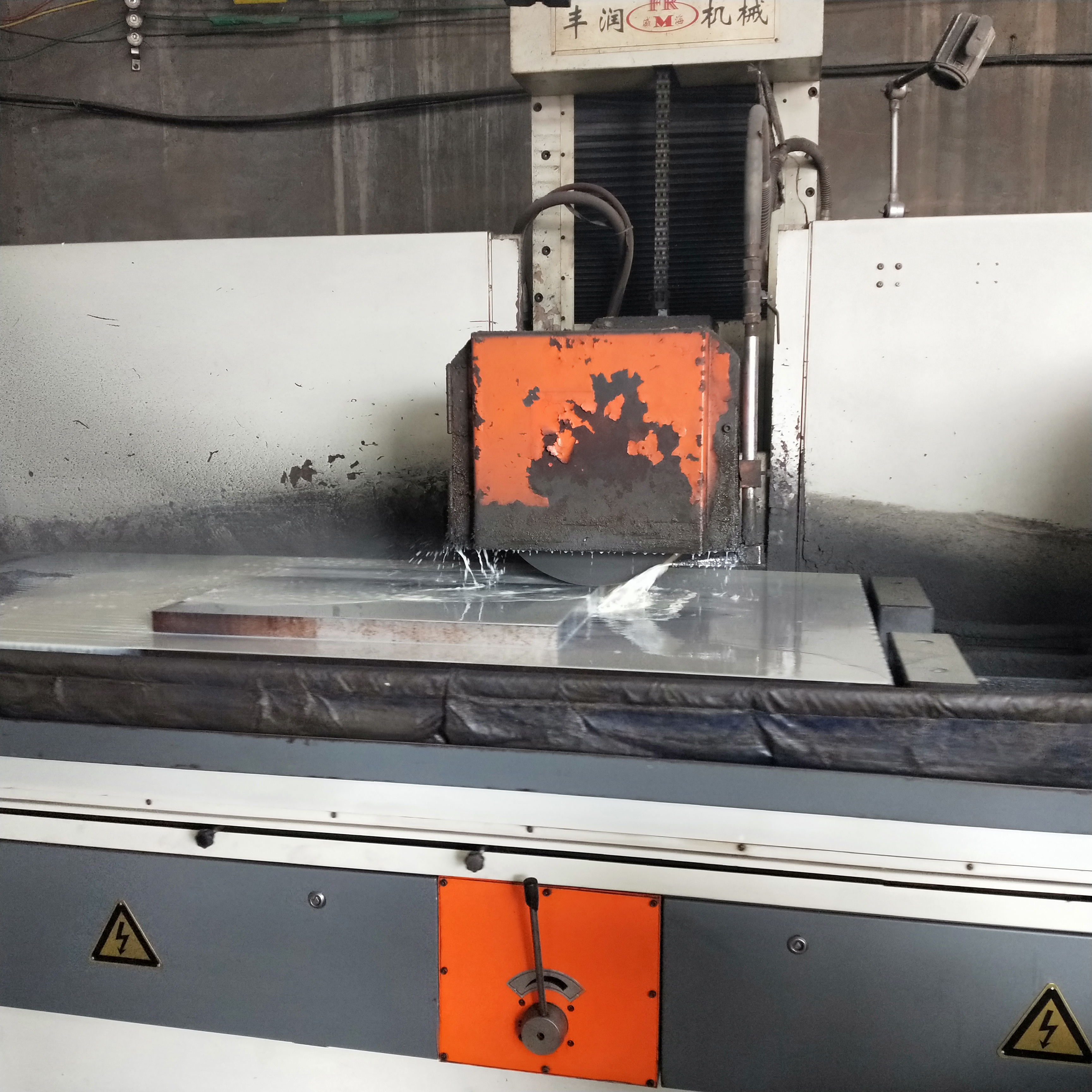

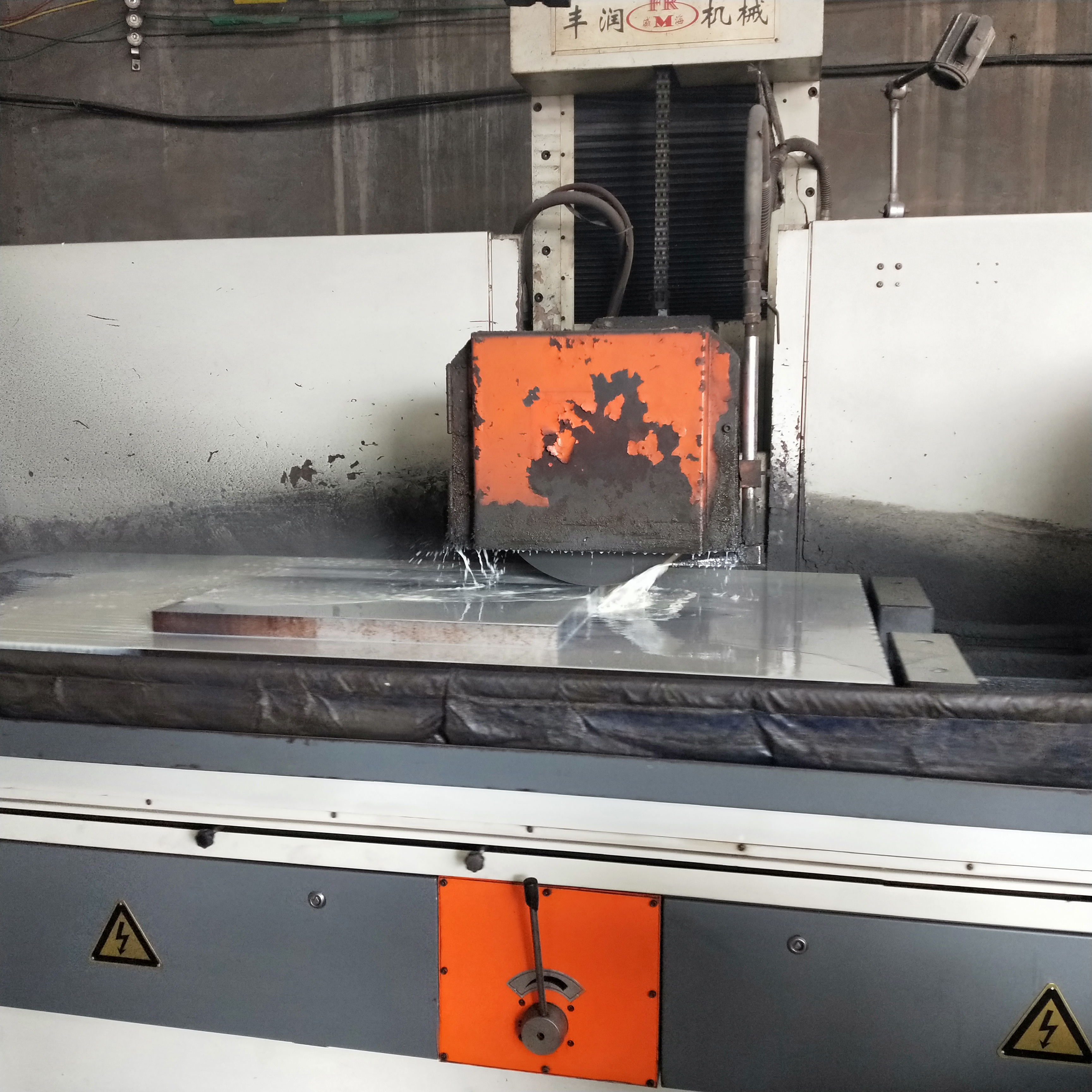

塑胶模具加工、工艺

Plastic mold processing and technology

工欲善其事,必先利其器。塑胶模具工艺的安排尤为重要,合理的工艺安排能加快生产周期,缩短加工时间,有效节省成本。而且更重要的是精确合理的加工能够保证模具在生产过程的稳定和延长寿命。加工出错有的会导致模具烧焊,无论焊的多好,对模具来说都是一种损失;另外加工不好还有可能影响模具动作,降低模具寿命,导致塑胶模具在生产过程中出现拉裂甚折断。

Sharp tools make good work. The process arrangement of plastic mold is particularly important. Reasonable process arrangement can speed up the production cycle, shorten the processing time and effectively save the cost. And more importantly, accurate and reasonable processing can ensure the stability of the mold in the production process and prolong the service life. Some processing errors will lead to die welding. No matter how good the welding is, it is a loss to the die; In addition, poor processing may also affect the action of the mold, reduce the service life of the mold, and cause the plastic mold to crack or even break in the production process.

上一条:

高热强性热作模具钢几种型号的优缺点

下一条:

模具钢材韧性值会标准化吗