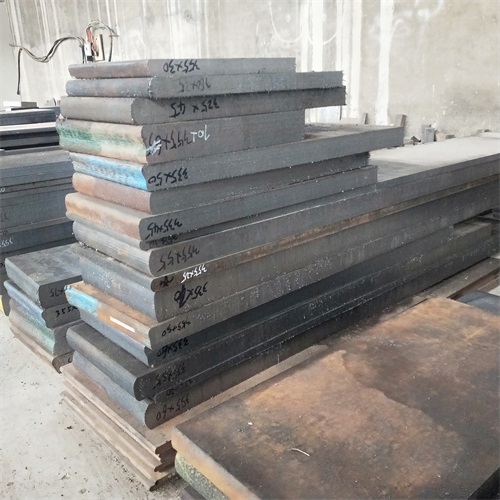

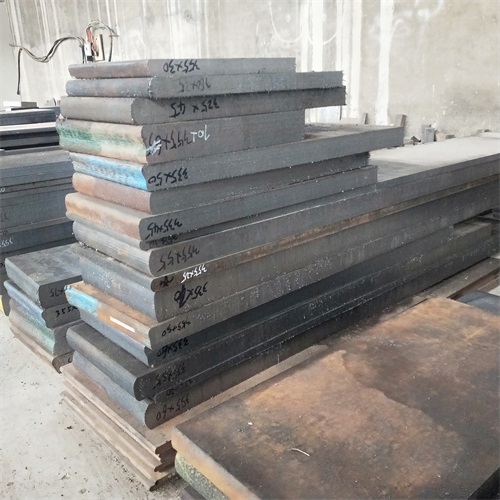

模具钢为什么会疲惫?如何推延模具钢的疲惫?这相关问题应该是大部分使用者都会关注到的事情,下面冷作模具钢厂家就来为您分析一番。

Why is die steel tired? How to prolong fatigue of die steel? This related problem should be something that most users will pay attention to. Now, the cold working die steel manufacturer will analyze it for you.

疲惫失效的特征,是在模具钢的某些部位,经过必定的执役期,萌发了细微的裂纹,并逐步向纵深扩展,裂纹扩展到必定的尺度后,严重削弱模具钢的承载才能而引起断裂。

The feature of fatigue failure is that in some parts of the die steel, after a certain period of service, tiny cracks sprout and gradually extend to the depth. When the cracks extend to a certain scale, they seriously weaken the bearing capacity of the die steel and cause fracture.

疲惫裂纹萌发于应力较大的部位,特别是有应力会集的部位(尺度过渡、缺口、刀痕、磨削裂纹等)。

Fatigue cracks germinate in the parts with high stress, especially those with stress concentration (scale transition, notch, knife mark, grinding crack, etc.).

疲惫断裂时,断口可分为两部分:一部分是疲惫裂纹开展形成的疲惫处破裂断面,出现贝壳状,疲惫源坐落贝壳极点;另一部分为突然断裂,出现不平整的粗糙断面。

When fatigue fracture occurs, the fracture can be divided into two parts: one part is the fracture section of the fatigue part formed by fatigue crack development, which appears as a shell, and the fatigue source is located at the shell pole; The other part is suddenly fractured with uneven rough section.

使模具钢产生疲惫损害的底子原因是循环载荷。凡促使外表拉应力增大的因素,均加速疲惫裂纹的萌发。

The ultimate cause of fatigue damage of die steel is cyclic load. All factors that promote the increase of external tensile stress accelerate the germination of fatigue cracks.

冷作模具钢在高硬度状态下执役,此时,模具钢钢具有很高的屈从强度和很低的断裂韧性。高的屈从强度有利于推延疲惫裂纹的萌发,但低的断裂韧性使疲惫裂纹的扩展速率加速和临界长度减小,使疲惫裂纹的扩展循环数大大缩短。因而冷作模具钢,其疲惫寿数首要取决于疲惫裂纹萌发时刻。

Cold work die steel is in service under the condition of high hardness. At this time, the die steel has high yield strength and low fracture toughness. High yield strength is conducive to delaying the germination of fatigue cracks, but low fracture toughness accelerates the growth rate of fatigue cracks and reduces the critical length, which greatly shortens the number of fatigue crack growth cycles. Therefore, the fatigue life of cold working die steel mainly depends on the time of fatigue crack germination.

模具钢疲惫的原因以及如何推迟这一问题就讲解到这里了,您对此有什么需求就来我们网站https://www.jnqhmj.com进行咨询吧!

The reason for the fatigue of die steel and how to delay the problem are explained here. If you have any needs, please come to our website https://www.jnqhmj.com Consult!

上一条:

模具钢材的变形主要原因