冷作模具钢包括冷冲模、冷挤压模、冷锻模、冷精压模等。冷作模具钢在工作中承受拉伸、压缩、弯曲、冲压、疲劳、摩擦等机械力的作用。模具常常发生裂纹及断裂、磨损、啃伤、疲劳、塑性变形等形式的失败。因此,冷作模具钢应具备哪些性能:

Cold working dies include cold stamping die, cold extrusion die, cold forging die, cold precision pressing die, etc. The cold working die bears the mechanical forces such as tension, compression, bending, stamping, fatigue and friction. The die often fails in the form of crack, fracture, abrasion, gnawing, fatigue and plastic deformation. Therefore, the cold working die steel should have what properties:

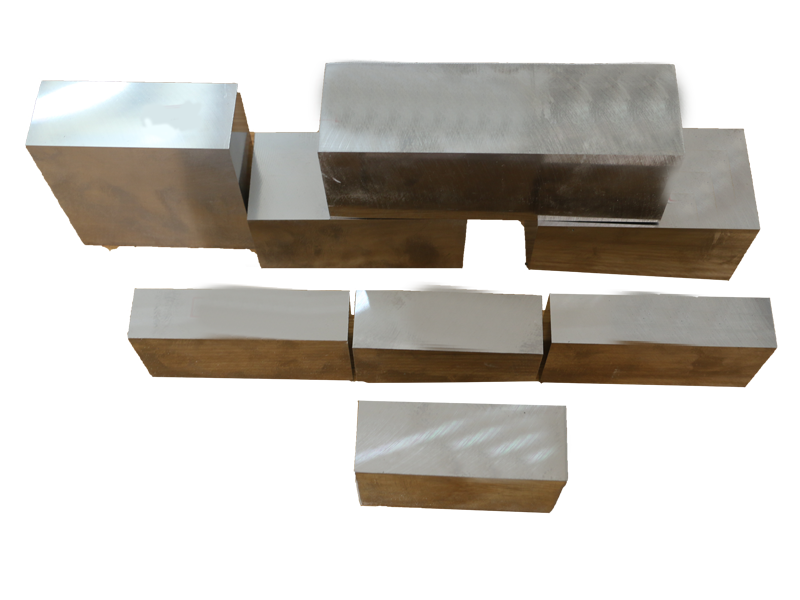

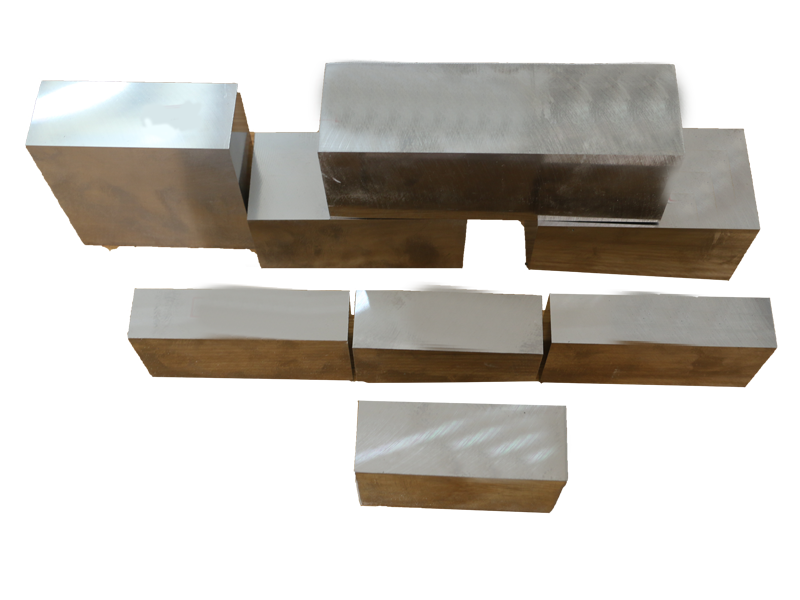

1、冷作模具钢使用范围非常广,可以用作建筑承载、也可以用来充当结构钢架,当然他的主要作用还是冲压切割,由于用途不一样,只能综合性地概括其特性。

1. Cold working die steel is widely used, which can be used as building bearing and structural steel frame. Of course, its main function is stamping and cutting. Due to different uses, its characteristics can only be summarized comprehensively.

2、较高的耐磨性:冷作模具在工作时,表面与坯料之间产生许多次摩擦,模具在这种情况下必须仍能保持较低的表面粗糙度值和较高的尺寸精度,以防止早期失效。

2. High wear resistance: when the cold working die is working, there are many times of friction between the surface and the blank. In this case, the die must still be able to maintain a low surface roughness value and high dimensional accuracy to prevent early failure.

3、较高的强度和韧性:模具的强度是指模具零件在工作过程中抵抗变形和断裂的能力。强度指标是冷作模具设计和材料选择的重要依据,主要包括拉伸屈服点、压缩屈服点等

3. High strength and toughness: die strength refers to the ability of die parts to resist deformation and fracture in the working process. Strength index is an important basis for cold working die design and material selection, including tensile yield point, compressive yield point, etc

4、要有良好的耐热性。尤其在高速冲压情况下,模具温度升高,形状尺寸应保持稳定。

4. Good heat resistance. Especially in the case of high-speed stamping, the mold temperature increases, the shape and size should be stable.

5、抗咬合性。主要针对拉深过程中常见镍基合金,奥氏体不锈钢、精密合金等材料有较强咬合倾向时,对模具材料提出的一种要求。当冲压材料与模具表面接触时,在高压摩擦下,润滑油膜被破坏,此时被拉深的金属“冷焊”在模具表面形成金属瘤,引起工作表面划出伤痕,出现残品,模具失效使拉深工作无法正常进行。抗咬合性就是对发生“冷焊”的抵抗力。影响搞咬合力的主要因素是成形材料的性质。冷作模具钢应润滑条件也对抗咬合性有较大影响。

5. Anti occlusion. This paper mainly aims at a kind of requirement for die material when common nickel base alloy, austenitic stainless steel and precision alloy have strong bite tendency in the process of deep drawing. When the stamping material contacts with the die surface, under high pressure friction, the lubricating oil film is destroyed. At this time, the "cold welding" of the deep drawing metal forms metal nodules on the die surface, causing the scratch on the working surface and the appearance of defective products. The die failure makes the drawing work unable to be carried out normally. Bite resistance is the resistance to cold welding. The main factor affecting the biting force is the property of the forming material. The lubrication condition of cold working die steel also has a great influence on the anti bite ability.

6、良好的冷、热加工工艺性能。如可锻性、可加工性、淬透性、淬硬性、热处理变形和较小的脱碳敏感性等。

6. Good cold and hot processing performance. Such as malleability, machinability, hardenability, heat treatment deformation and low decarburization sensitivity.

上一条:

冷作模具钢的使用性能要求及分类

下一条:

模具钢中耐热钢和耐热合金的分类